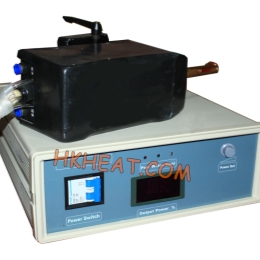

HK-60AB-UHF ultra high frequency induction heater

Specification of (UHF) Ultra-High Frequency Induction Heating Machines:

| Type | Rated Power | Max. Input Current | Max. Absorbed Power | Max. Frequency | Input Voltage | Cooling Water | Normal Size (cm) | Net Weight(kg) |

|---|---|---|---|---|---|---|---|---|

| HK-05AB-UHF | 6KVA | 23A | 5KW | 1.5MHz | 220VAC, 50Hz, Single Phase | >0.2 MPa, 2-5 L/Min, <40 oC |

Main: 43X35X13 Head: 23X10X12 |

10+6 |

| HK-06A-UHF | 6.5KVA | 27A | 6KW | 1.1MHz | 220VAC, 50Hz, Single Phase | >0.2 MPa, 5 L/Min, <40 oC | 58X26X50 | 23 |

| HK-06AB-UHF | 6.5KVA | 27A | 6KW | 1.1MHz | 220VAC, 50Hz, Single Phase | >0.2 MPa, 5 L/Min, <40 oC |

Main: 52X24X50 Head: 14X14X10 |

17+6 |

| HK-10A-UHF | 12KVA | 15A | 10KW | 900KHz | 380VAC, 50Hz, Three Phase | >0.2 MPa, 5 L/Min, <40 oC | 58X26X50 | 30 |

| HK-10AB-UHF | 12KVA | 15A | 10KW | 900KHz | 380VAC, 50Hz, Three Phase | >0.2 MPa, 5 L/Min, <40 oC |

Main: 52X24X50 Head: 14X14X10 |

26+6 |

| HK-20A-UHF | 23KVA | 30A | 20KW | 600KHz | 380VAC, 50Hz, Three Phase | >0.2 MPa, 5 L/Min, <40 oC |

Main: 55X35X45 |

35 |

| HK-20AB-UHF | 23KVA | 30A | 20KW | 600KHz | 380VAC, 50Hz, Three Phase | >0.2 MPa, 5 L/Min, <40 oC |

Main: 55X25X45 Head: 49X26X37 |

29+24 |

| HK-30AB-UHF | 34KVA | 45A | 30KW | 500KHz | 380VAC, 50Hz, Three Phase | >0.2 MPa, 5 L/Min, <40 oC |

Main: 55X25X45 Head: 49X26X37 |

32+25 |

| HK-40AB-UHF | 45KVA | 61A | 40KW | 400KHz | 380VAC, 50Hz, Three Phase | >0.2 MPa, 7.6 L/Min, <40 oC |

Main: 65X34X55 Head: 51X30X45 |

49+28 |

| HK-60AB-UHF | 66KVA | 90A | 60KW | 400KHz | 380VAC, 50Hz, Three Phase | >0.2 MPa, 10 L/Min, <40 oC |

Main: 65X34X55 Head: 51X30X45 |

52+30 |

| HK-80AB-UHF | 80KVA | 120A | 80KW | 400KHz | 380VAC, 50Hz, Three Phase | >0.2 MPa, 20 L/Min, <40 oC | customized | customized |

| HK-100AB-UHF | 110KVA | 150A | 100KW | 400KHz | 380VAC, 50Hz, Three Phase | >0.2 MPa, 25 L/Min, <40 oC | customized | customized |

| HK-120AB-UHF | 130KVA | 180A | 120KW | 400KHz | 380VAC, 50Hz, Three Phase | >0.2 MPa, 30 L/Min, <40 oC | customized | customized |

| HK-160AB-UHF | 180KVA | 240A | 160KW | 400KHz | 380VAC, 50Hz, Three Phase | >0.2 MPa, 30 L/Min, <40 oC | customized | customized |

| HK-200AB-UHF | 210KVA | 300A | 200KW | 400KHz | 380VAC, 50Hz, Three Phase | >0.2 MPa, 40 L/Min, <40 oC | customized | customized |

Application Fields of Induction Heating

-

Brazing by induction will bring a better brazing effect.

-

A quick and better way for foring works

-

A quicker melting method

-

The best quenching method

-

A better tempering method

-

With flexible induction coil, cool

-

Many solution for induction heating.

Advantage of Induction Heating

-

Optimized Consistency

Induction heating eliminates the inconsistencies and quality issues associated with open flame, torch heating and other methods.

Maximized Productivity

Induction works so quickly, heat is developed directly and instantly (>1000℃. in < 1 second) inside the part.

-

Improved Product Quality

With induction, the part to be heated never comes into direct contact with a flame or other heating element, the heat is induced within the part itself by alternating electrical current.

Extended Fixture Life

Induction heating rapidly delivers site-specific heat to very small areas of your part, without heating any surrounding parts, this extends the life of the fixture and mechanical setup.

-

Environmentally Sound

Induction heating systems do not burn traditional fossil fuels, induction heating is a clean, non-polluting process which will help protect the environment.

Reduced Energy Consumption

This uniquely energy-efficient process converts up to 95% of the energy expended energy into useful heat;

batch furnaces are generally only 45% energy-efficient. And since induction requires no warm-up or cool-down cycle, stand-by heat losses are reduced to a bare minimum.

-

Induction heating is able to heat different shapes of work-piece by customized induction coils.

Induction heating is a quick, safe, clean, environmentally friendly method for melting works

HK-60AB-UHF induction heater

Newest Comment

no comment

Leave Comment